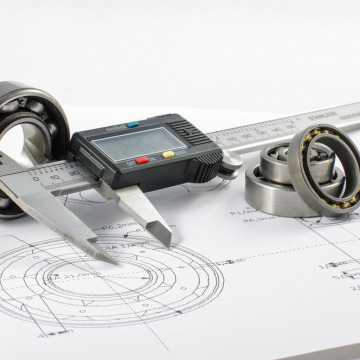

Manufacturing Quality Inspection Services

Since 2004 we have been helping our customers succeed with their products. With that experience, we have honed our service offering to do what really matters when improving product quality. If you are an OEM or a product supplier we have you covered.

Industries

Medium / Heavy Duty Truck

From trucks to tractors to snowmobiles, QLS works with equipment manufacturers like you who depend on high quality parts delivered to their assembly lines on a just-in-time basis.

Learn More

Industries

Construction / Agriculture

QLS performs agriculture and construction inspection services, product certification and when needed repairs production parts before they become the manufacturer’s bottleneck.

Learn More

Industries

Defense / Aerospace

QLS combines on-site assistance at both the OEM and supplier facilities to ensure on-time shipments and quality accuracy within the Aerospace and Defense Industry.

Learn More